|

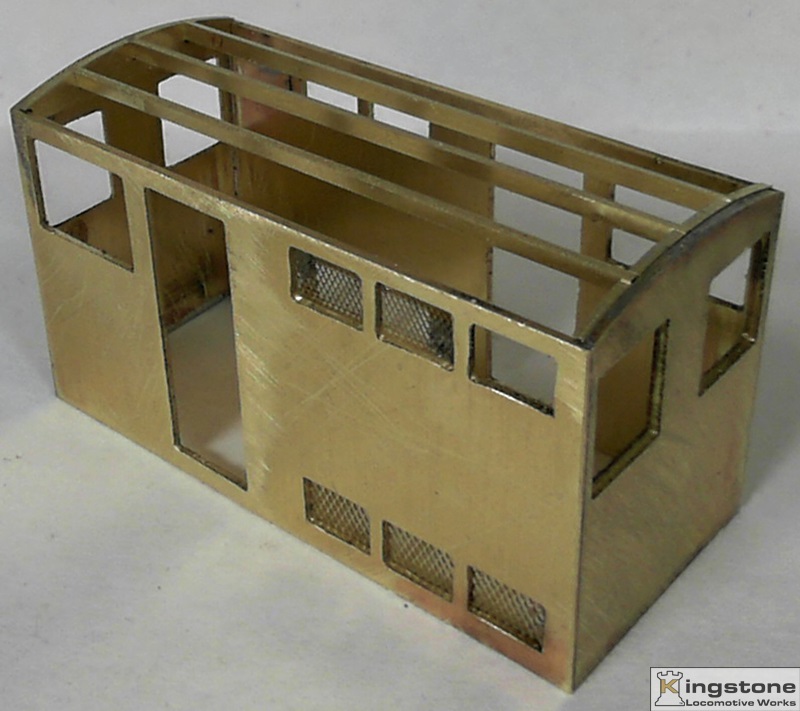

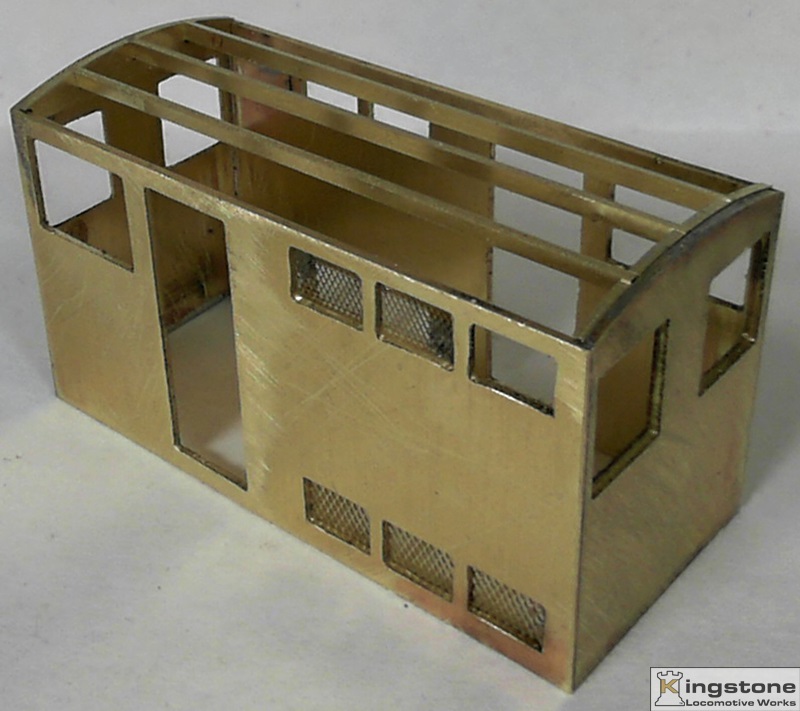

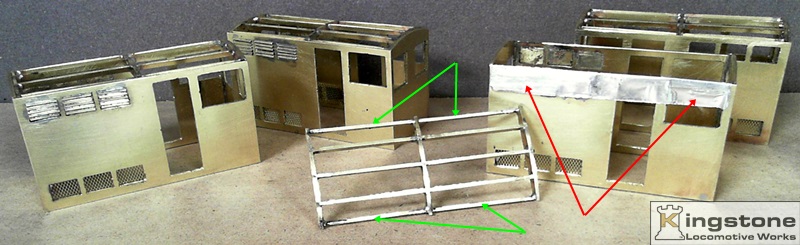

Working on making a rounded roof. The screens

have been installed in the bottom openings.

|

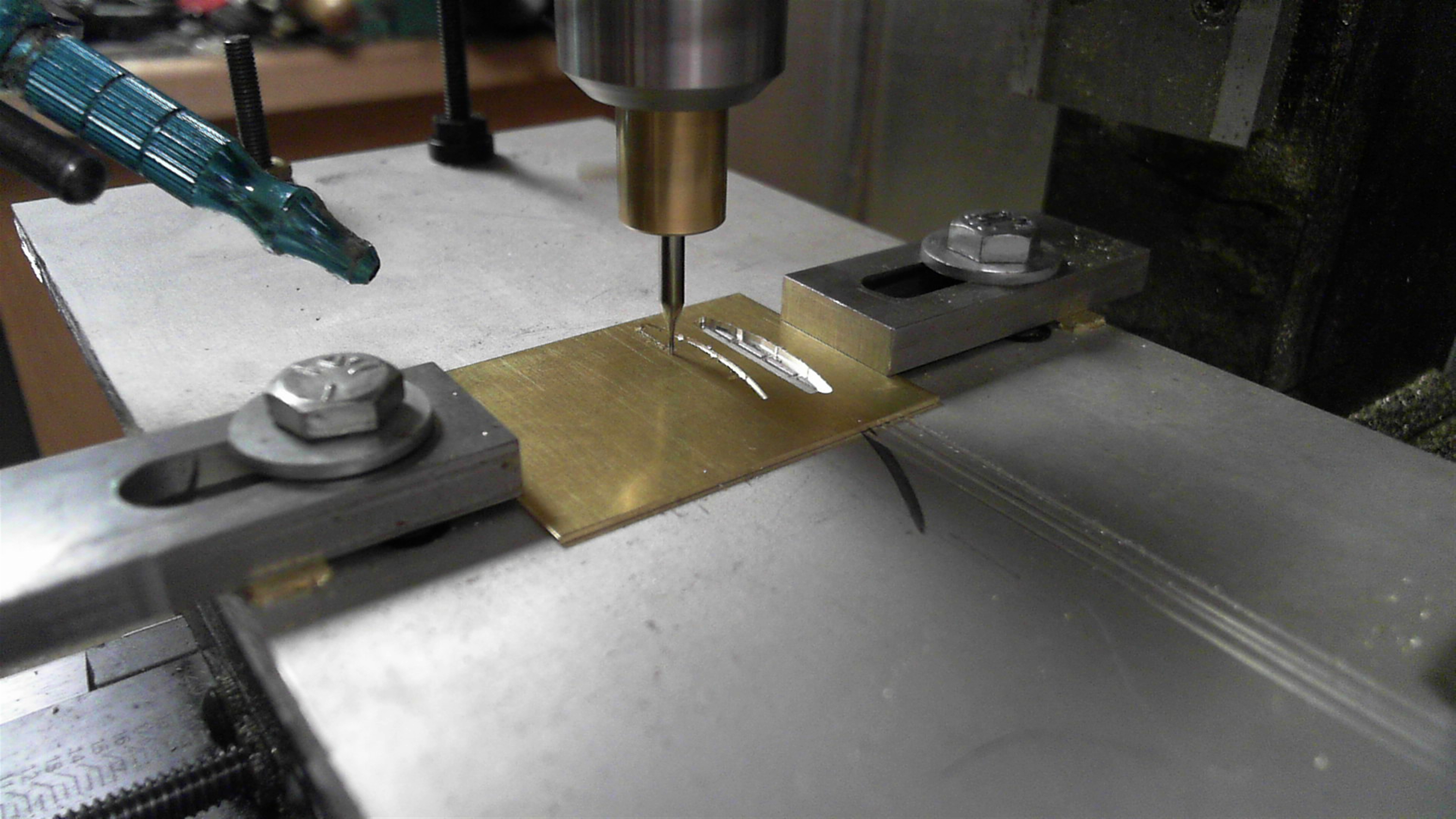

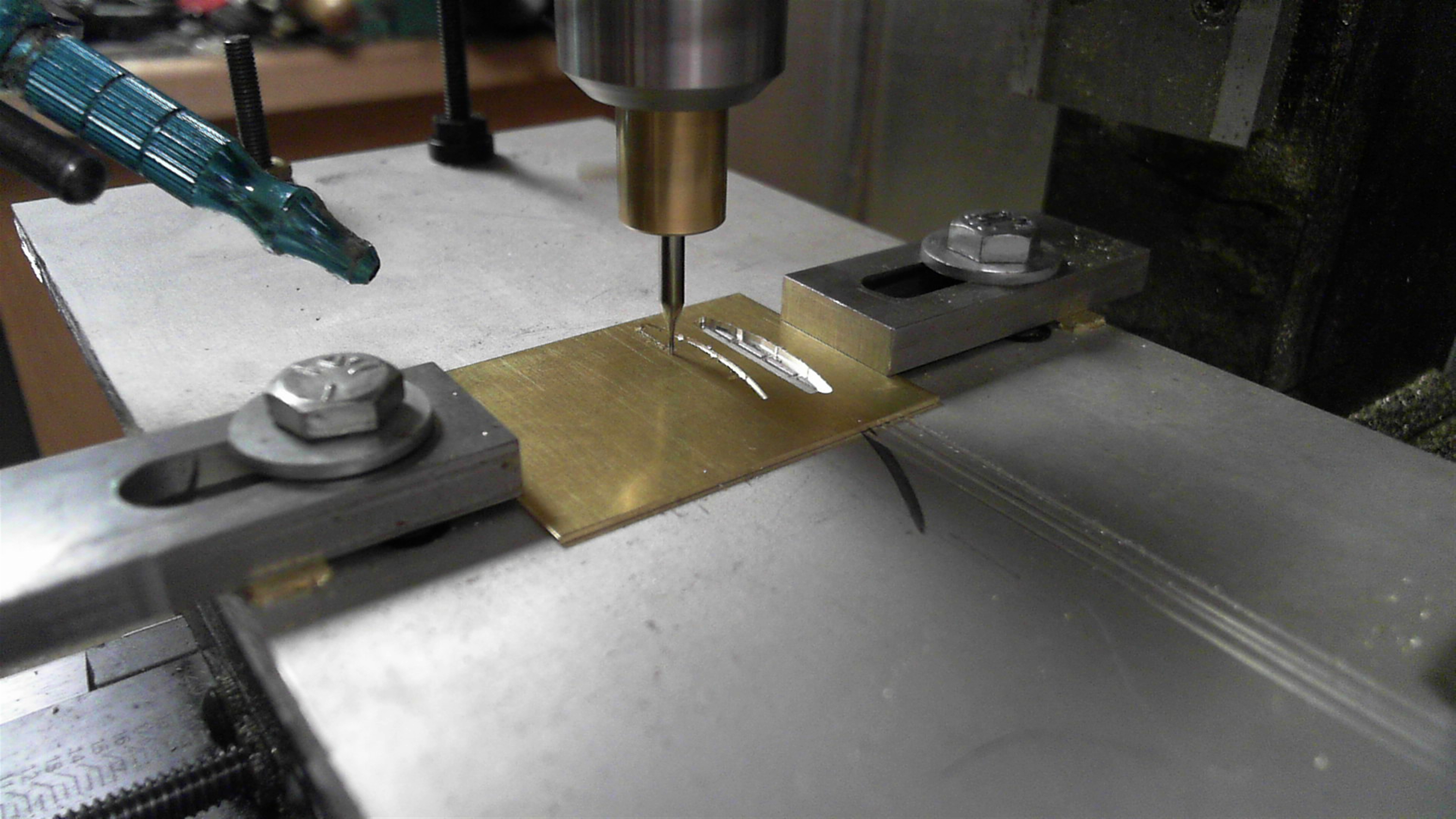

First some CAD work. After that the mill was put to work to

crank out a dozen or so parts, the last as accurate as the first.

|

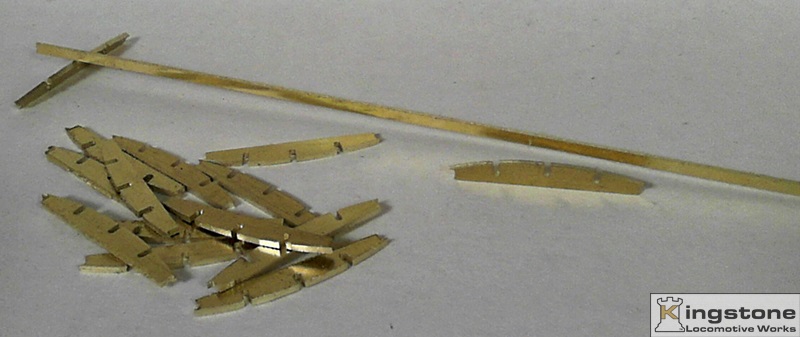

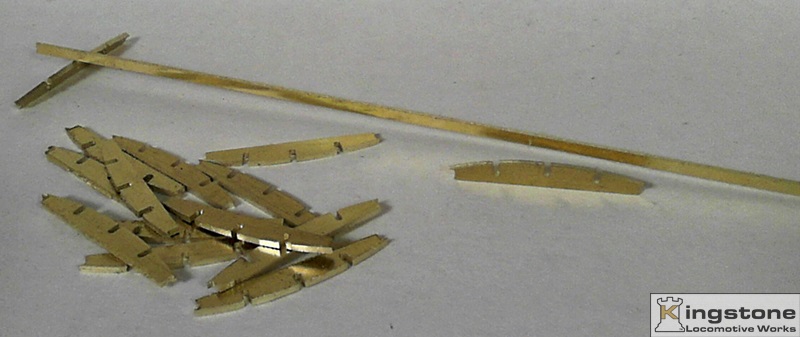

The parts to make up the sub-roof (?). About a dozen end pieces and a strip .030"

thick by .057" wide. The strip will be trimmed to length and will fit in the .0315" slot.

|

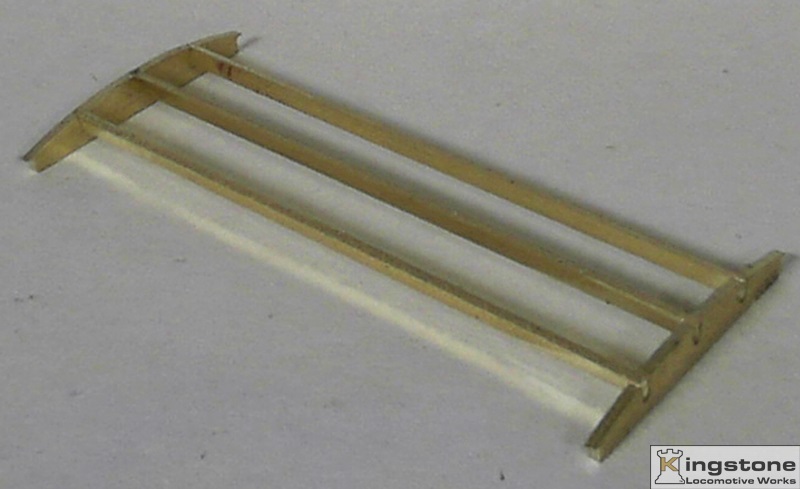

Here is one sub-roof assembled. The purlins were a sung fit in the slots and required a little persuasion with a

hammer. The nice thing about that is I don't need to make a

jig to hold everything together for soldering.

|

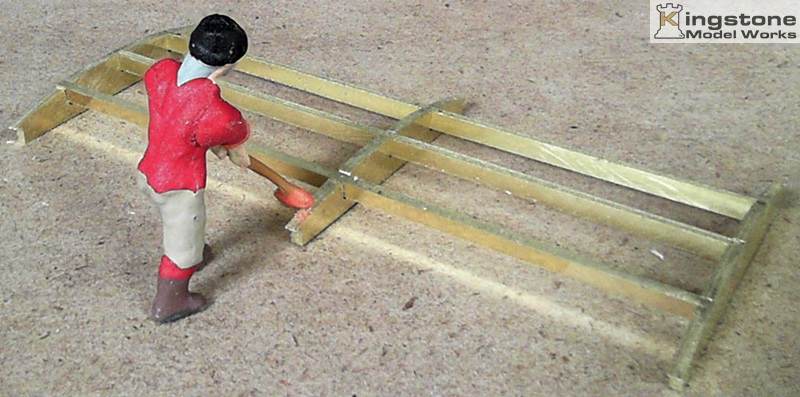

A nice snug fit.

|

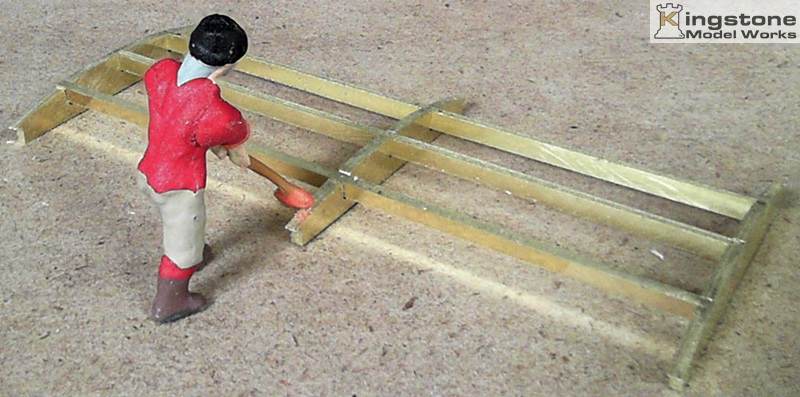

Added a center piece to make stringers more ridgit. My helper making an adjustment.

|

I flattened a piece of solder so I could find out how wide to cut the roof section.

|

The outside stringers first needed be soldered on. Since the cab side is also brass I would probably

solder the stringers to the side of the cab no matter how careful I was.

A piece of aluminum foil to

the rescue. I folded it over the side and it'll prevent the stringers from getting soldered to the sides.

The green arrows point to the outside stringers and the

red arrows point to the aluminum foil.