Electric Boxcab

NOTE:Click on picture to enlarge. Click back button on your browser to return to this page. |

|

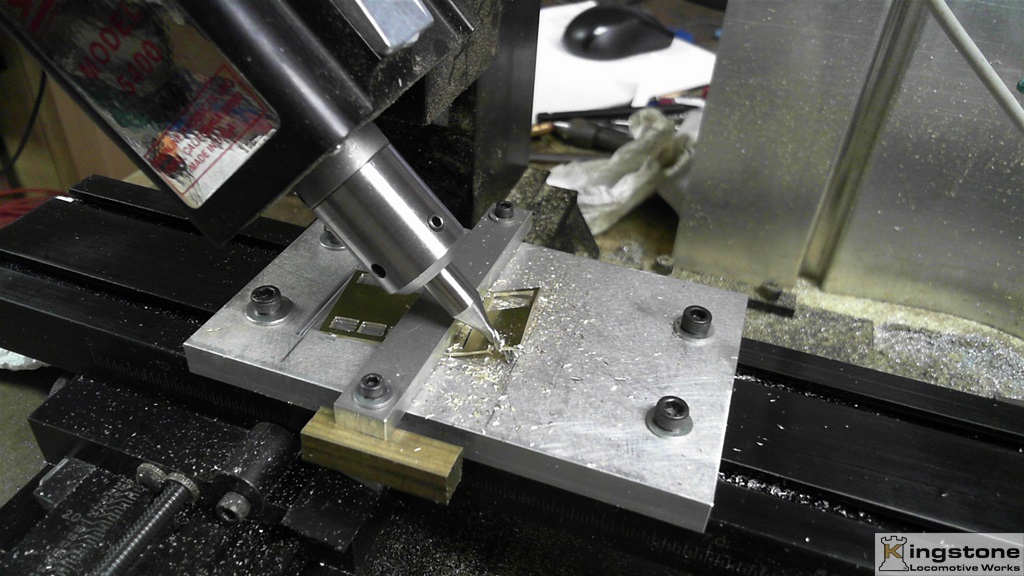

One of 8 sides having the angle milled on.

|

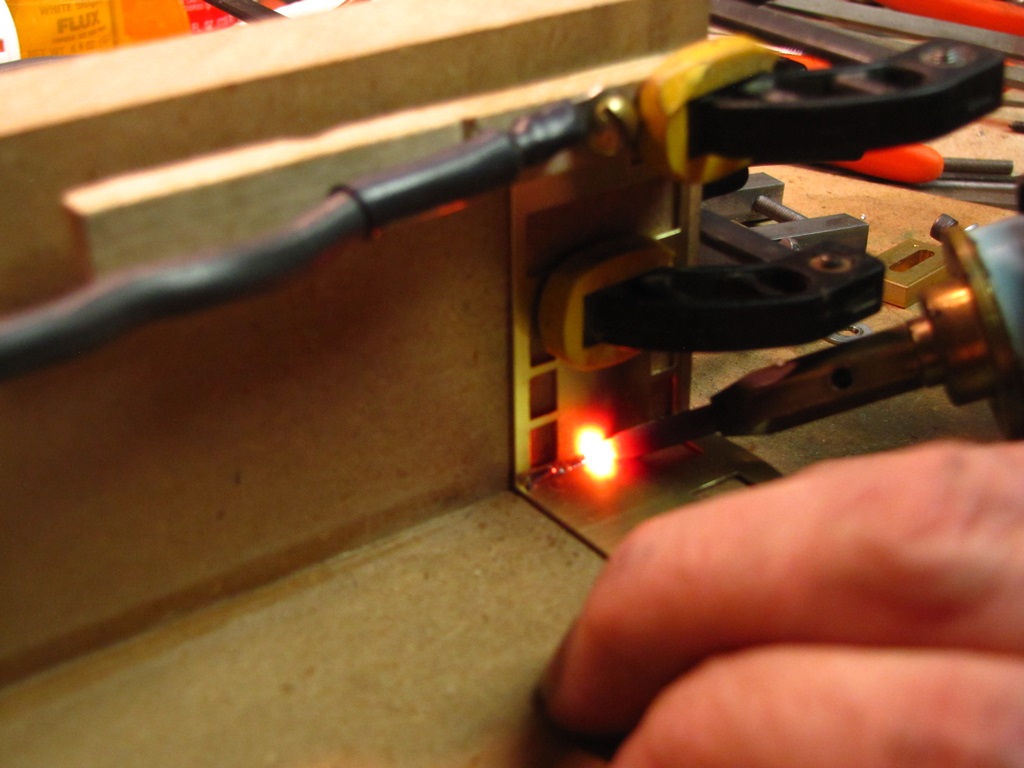

After I got all the pieces milled it was, as Norm Abram's says, time for a little assembly.

I made a fixture to hold the pieces

90° to each other and used my resistance soldering

unit with a carbon rod to solder the pieces together.

|

And the end results of a couple of hours of work are three roughed in boxcab's.

|

Why only three when I said I was making four? Well the

machine got hungry and decided to eat one of the sides.

That's the one nice thing about using CNC. You can make an identical part again

with much less effort.Next step is to start adding the

details, such as doors, louvers

and start thinking about how I'm going to do the roof. Lots of engineering going on here.

|

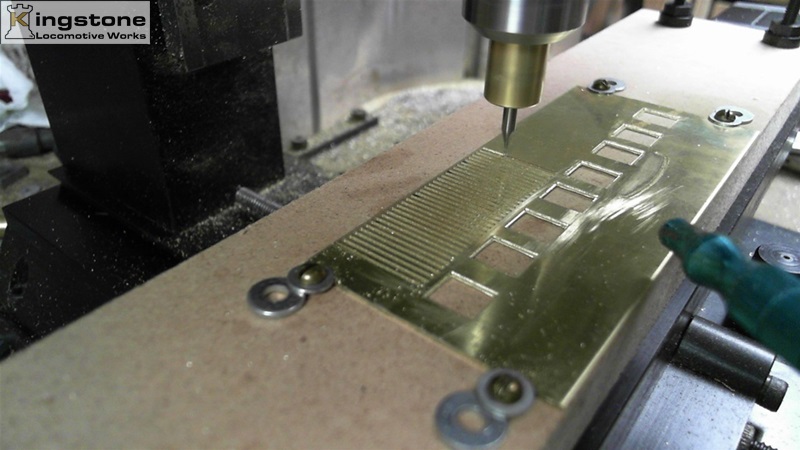

Working on the details of the boxcab. I made some louvers for the boxcab.

From a quick tally it looks like I would need 36 sets

of louvers for the three bodies I have now.

Don't know if I'll have the patients to do that many.

Here's what's involved with making a set

of louvers. It takes 5 pieces of stock approximately 1/32" square with a 45° angle milled on one

side. Those

pieces are them cut out of the milled pieces are soldered to a backing. Then a piece is

cut off to the length of the opening and trimmed to fit.

First the slots are milled on a 1/32" spacing.

|

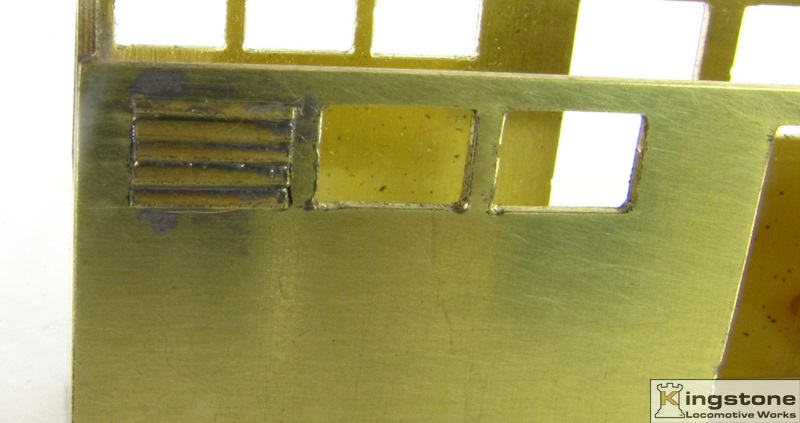

Then the 45° angled is milled on.

|

The milled angles actually look more triangles. They are cut off the main piece and are soldered

on to a .020" thick piece of brass.

It is then cut to length or close to it to fit into the opening

cut into the cab sides.

Here's a piece sitting on a penny to show just how big they are.

|

The part is then trimmed to fit in the cutout.