|

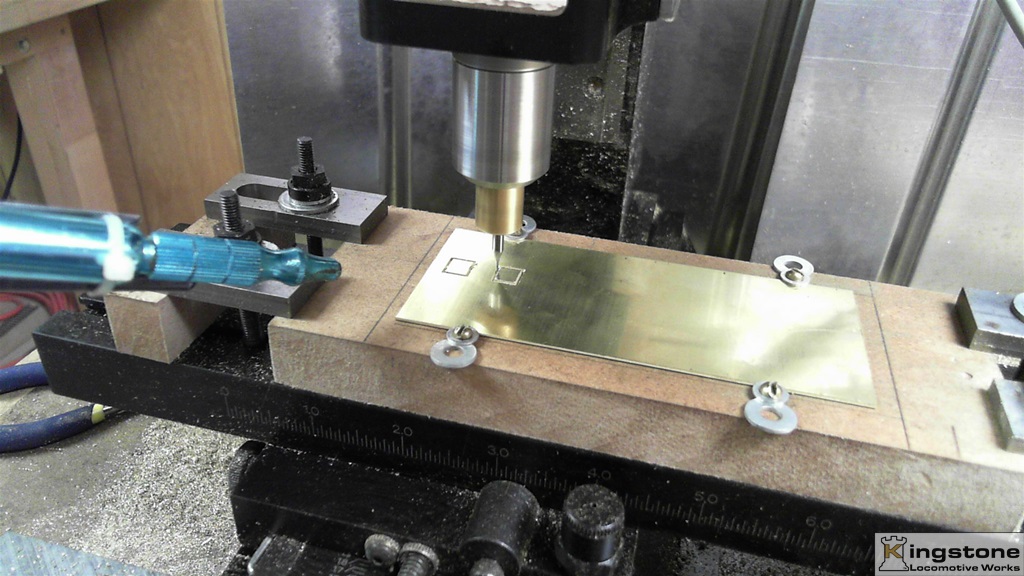

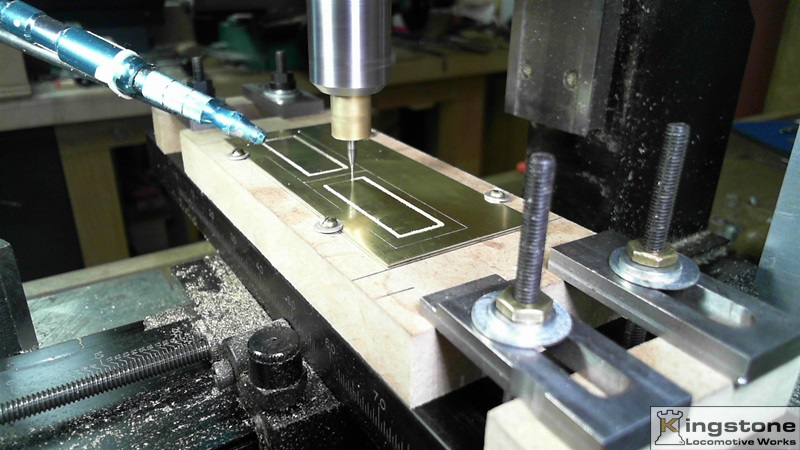

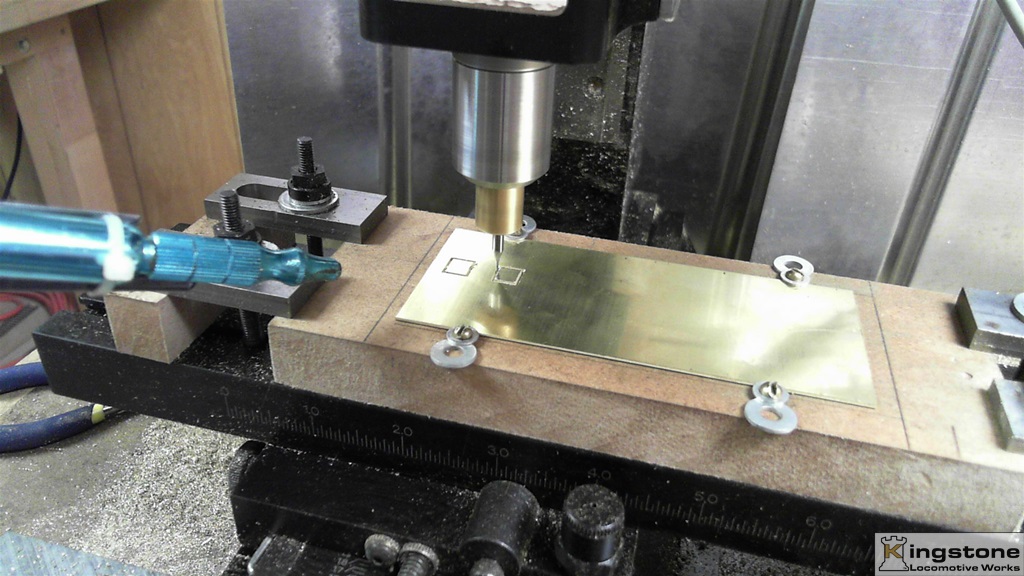

Cutting out three more frames with the fret saw was a bit of work. I figured I'd

use my Sherline CNC mill to do the work. More on using the Sherline mill later. I

used a piece of medium density fiber board with four wood screws and flat washers

to hold the .030" thick brass plate down. Three cuts at .010" deep was used to cut

through the plate

using a 1/32" dia. cutter.

|

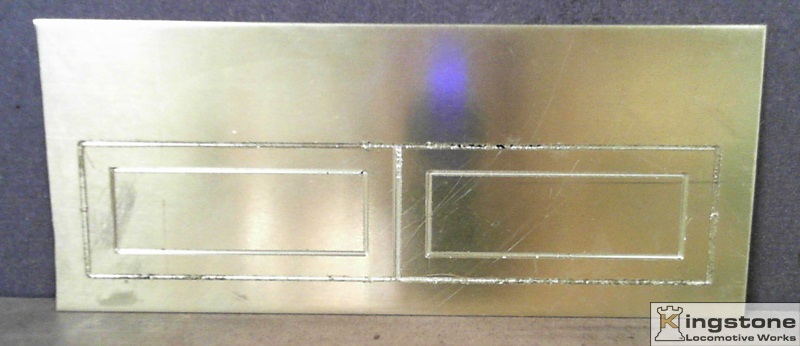

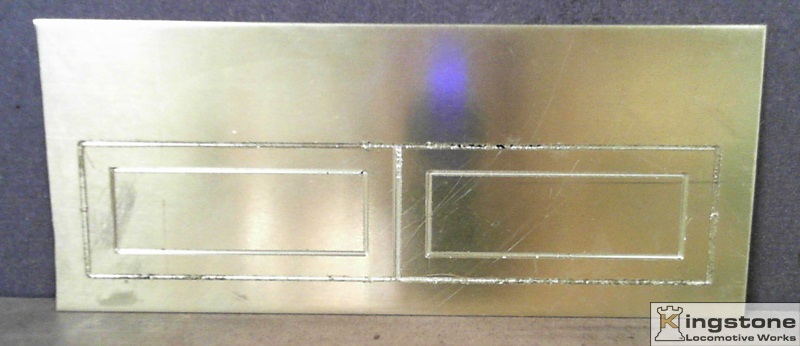

Didn't quite cut all the way through. That's 1/32" thick half hard brass plate.

|

I thought I had four chassis' but discovered I only had three.

|

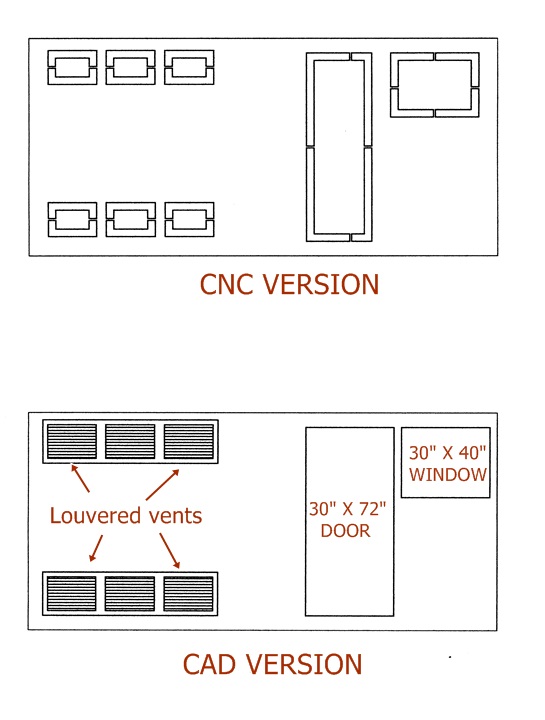

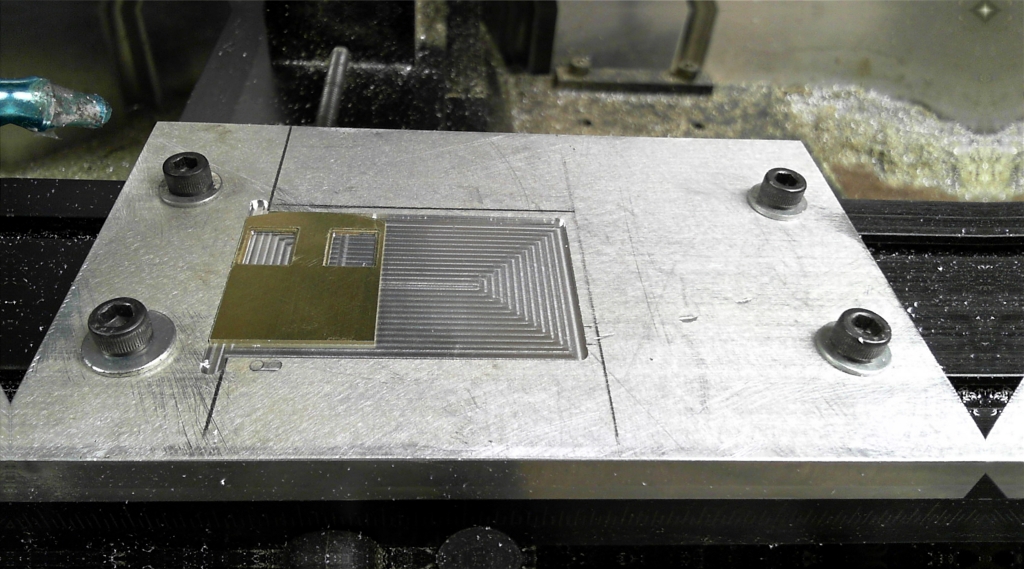

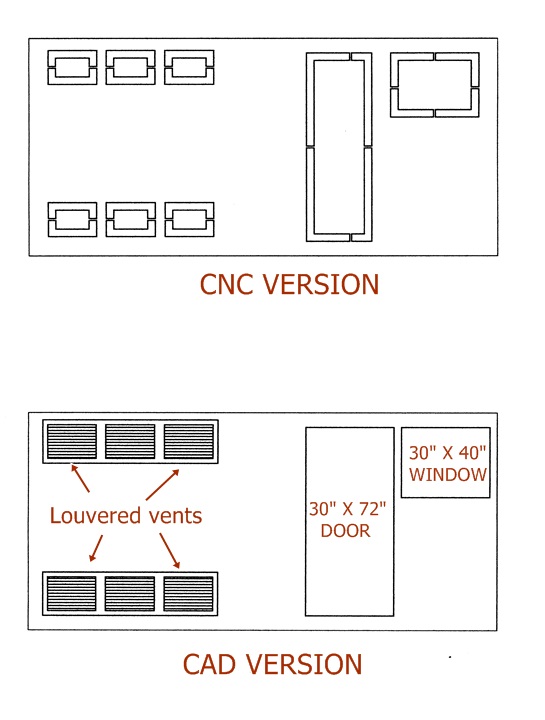

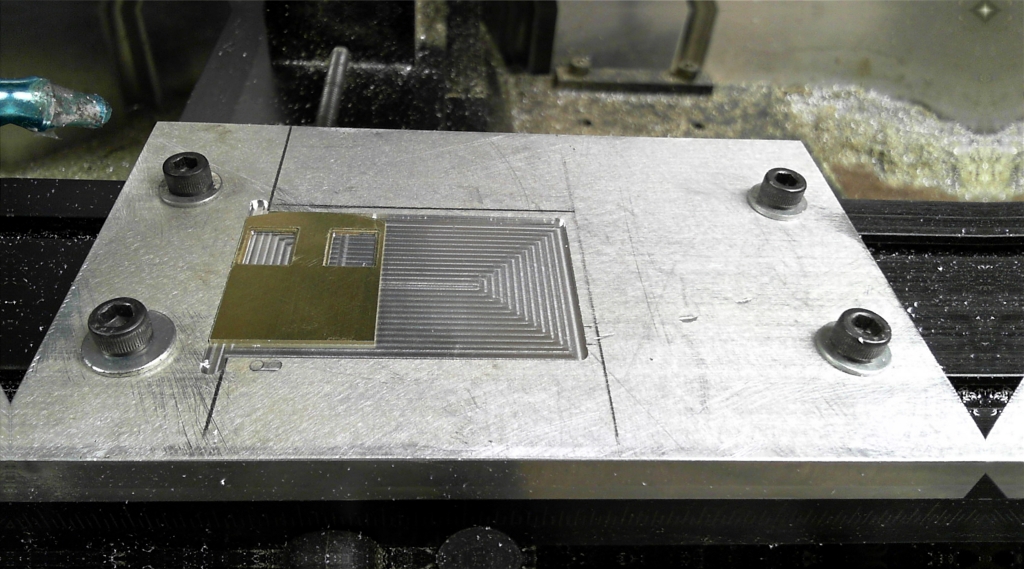

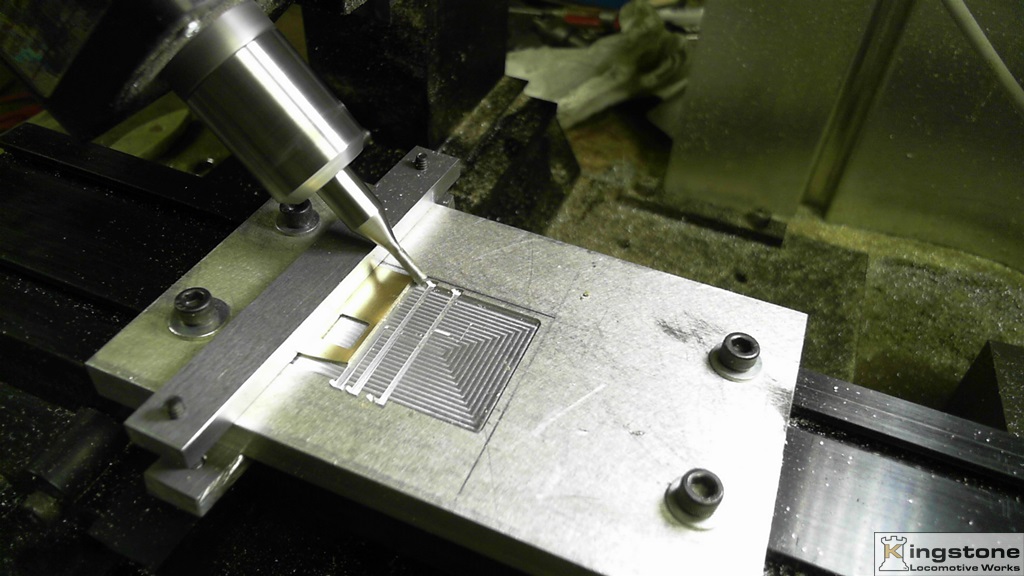

The CNC version shows the tabs left so the part

doesn't get tangled in the cutter at the end of the cut.

|

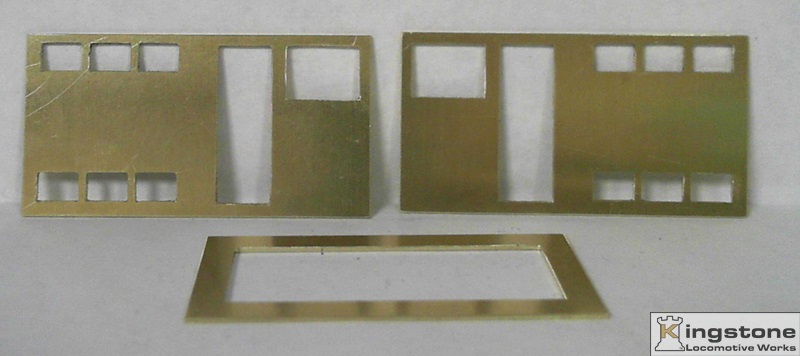

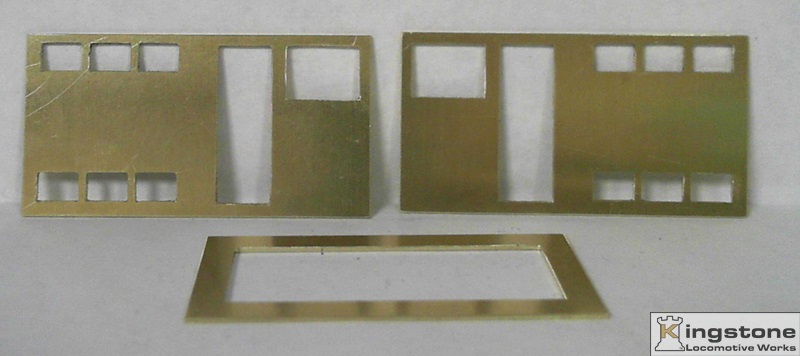

The finish cut parts.

|

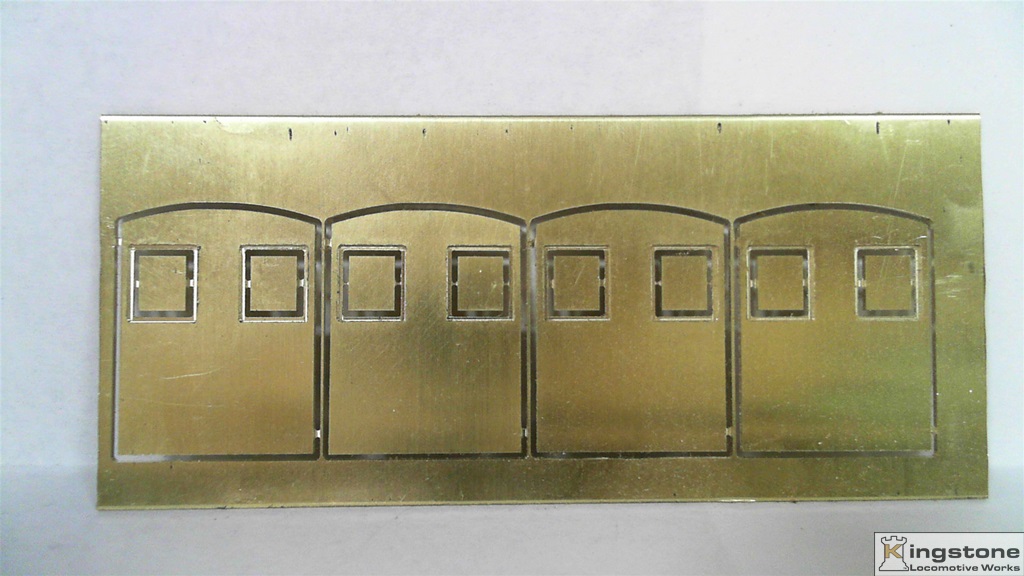

I finally got to cut out the first two sides of eight total that I will need.

It takes almost 8 hours to cut out two sides when taking only a .010" deep cut.

|

The tabs are cut out and the burrs filed off.

|

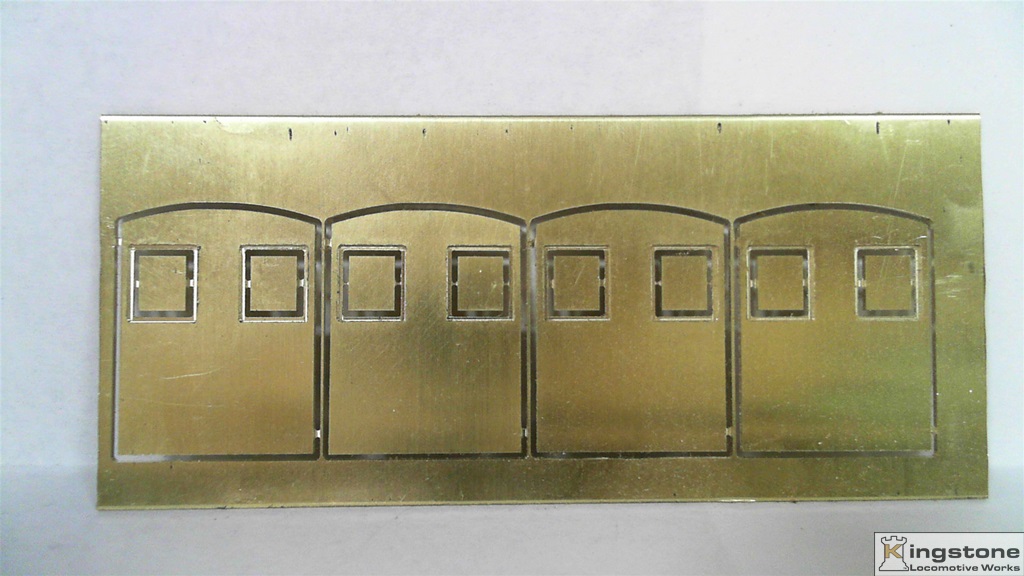

The first set of 8 ends. This is the start. The windows are being cut out. The nice thing is

I was able to mill out a very narrow section in the window to form the window frame.

|

Here's the end result. The nice thing is you can leave small tabs on the material so the

part won't get wrapped up in the cutter when the last little bit of material is cut out.

|

In order to get a nice corner when soldering the pieces together I made a jig so I

could mill a 45° angle on the ends of the pieces. Same idea when you are building

a wooden structure

and join them at the corners.

![]()