Mantua 2-6-6-2T Engine Tune Up

NOTE:Click on picture to enlarge. Click back button on your browser to return to this page. |

|

|

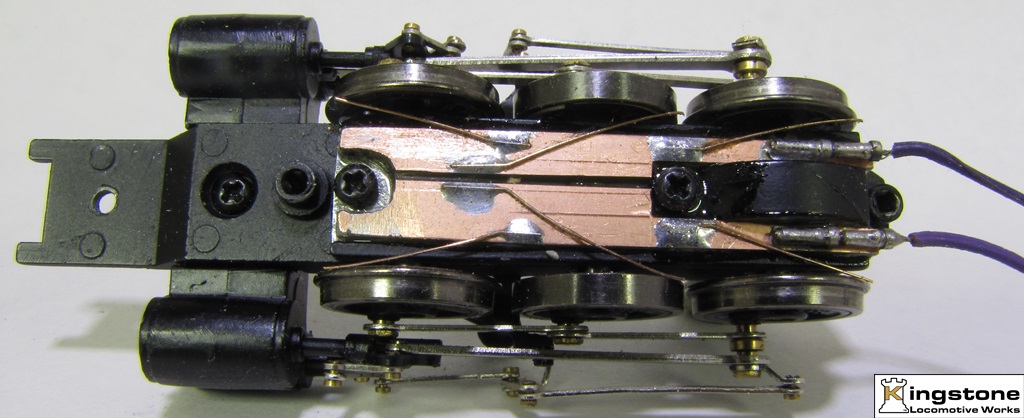

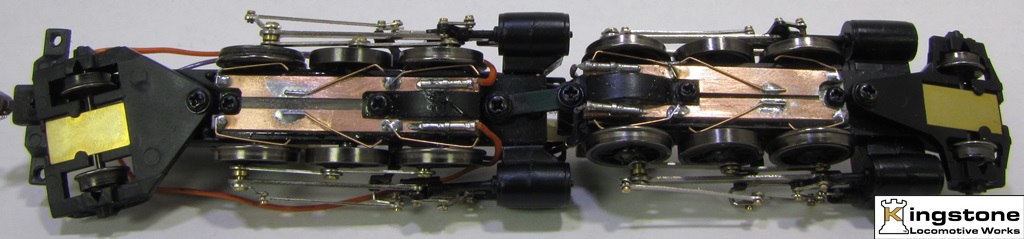

Once all the wiper wires were attached it was time to route some wires. To make a neat wire harness I fastened the wires with

some homemade eye bolts.

I used two different color wires. One for the front engine, purple/blue and red for the back. No reason.

I just had those available at the time. You may want to use black

and red for your project.

|

|

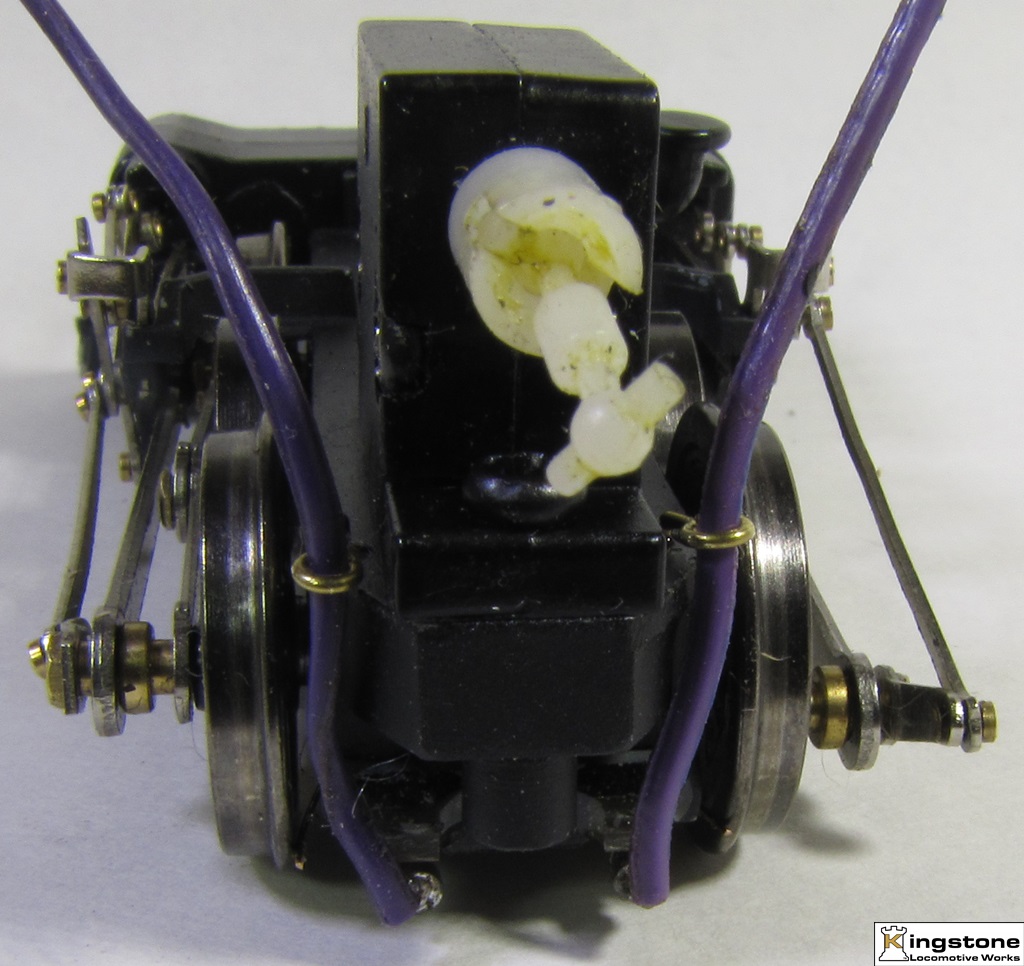

To neatened up the wire routing I made eye bolts out of brass wire.

I formed a loop big enough for the wire to fit through.

This made

routing the wires much easier and neater. I drilled a hole a bit smaller

that the wire diameter and ACC glued in the wire.

|

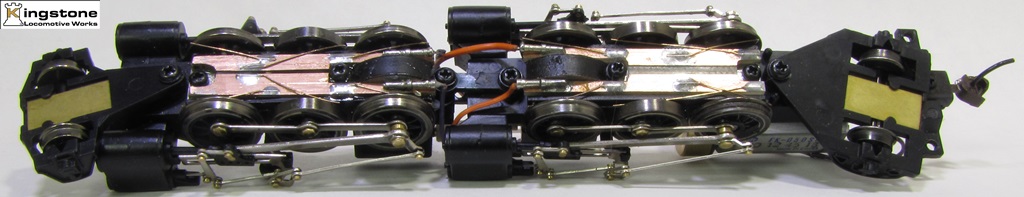

And all the wires installed and ready for a test run.

I temporarily wired the front and rear engine together and then on to the motor. I set it on the tracks and ..........nothing.

A dead short. Those plugs

came in handy. Started checking with continuity meter. Dead short across the wheels. Pulled the plugs

and everything OK. ??Must be the wiring. Nope. Then it

came to me. The front engine has the insulated wheels on one side and

the rear engine has the insulated wheels on the opposite side. So the front engine picks up power

on one side and on the other

side on the rear engine. Solution? Flip the wheels around on one engine so the insulated are all on one side. Easier said than done.

Once

that was done back on the tracks and whalla a running engine.

|

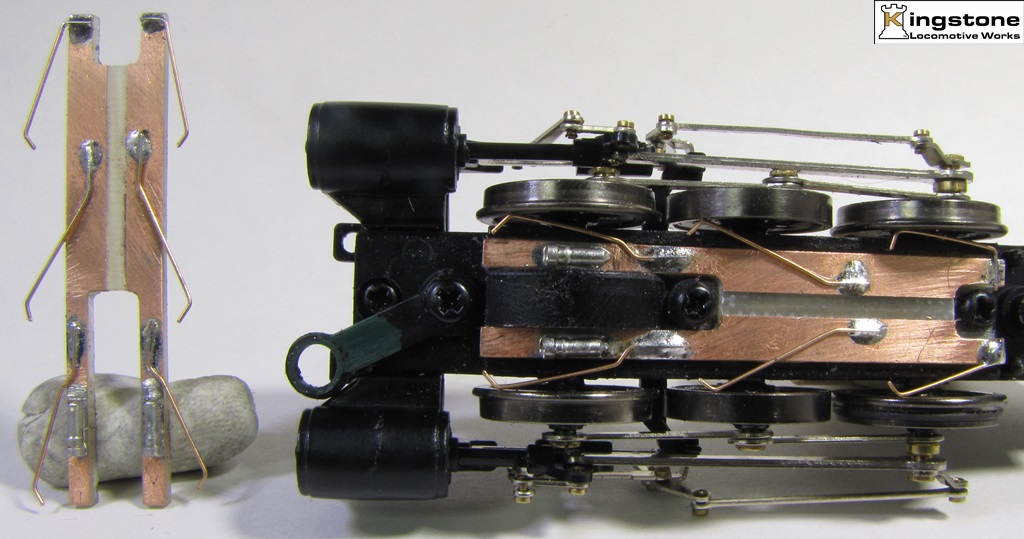

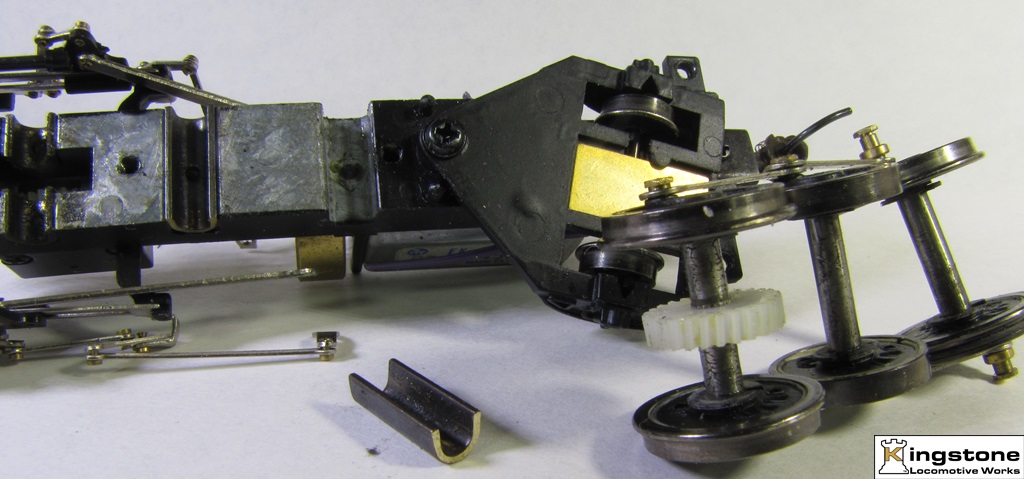

Next up is taking care of that side-to-side excessive play in the wheels. I made a washer from nylon. I did use my lathe for that.

I'm sure you can make

a washer without a lathe. The hole doesn't need to be perfect or even the OD of the washer. Not wanting to

remove the wheels to get a solid washer on and have to re-quarter

the divers I thought I give the split washer a try.I turned down

a 5/8" diameter nylon rod to an outside diameter of .250" (1/4") with a .125" (1/8") diameter hole, the size

of the axle. I sliced

off washers .015" thick and cut a pie slice out of it.

|

The bearing shells need to narrowed due to the shims added to the axles.

Once the engine was running to my statisfaction with the wiring it was time to run the wiring for the lights and reassemble the shell. That'll be next.