![]()

![]()

|

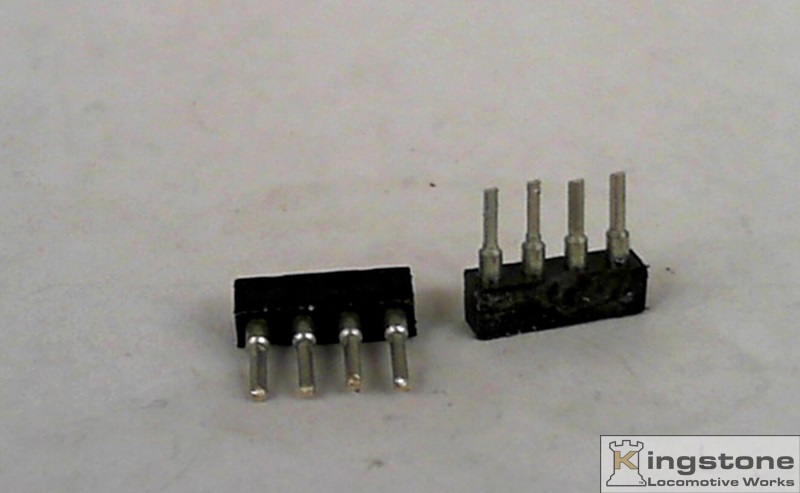

This is the 28 pin DIP socket I use for male pins. |

|

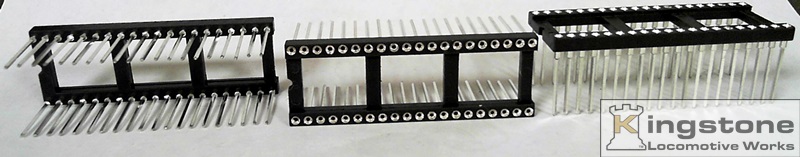

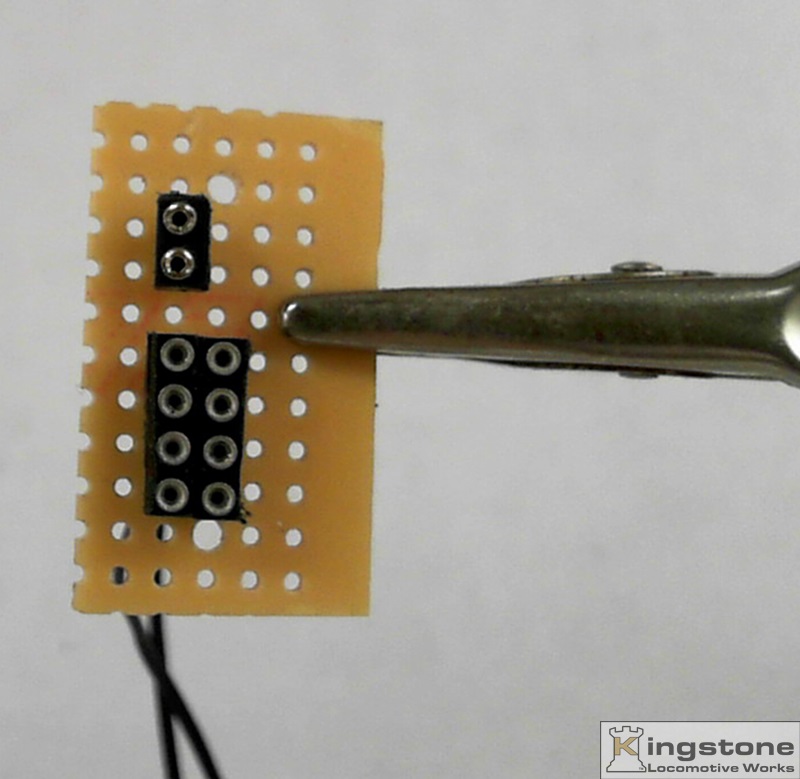

These are the 40 pin DIP wire wrap sockets I use for female sockets. |

|

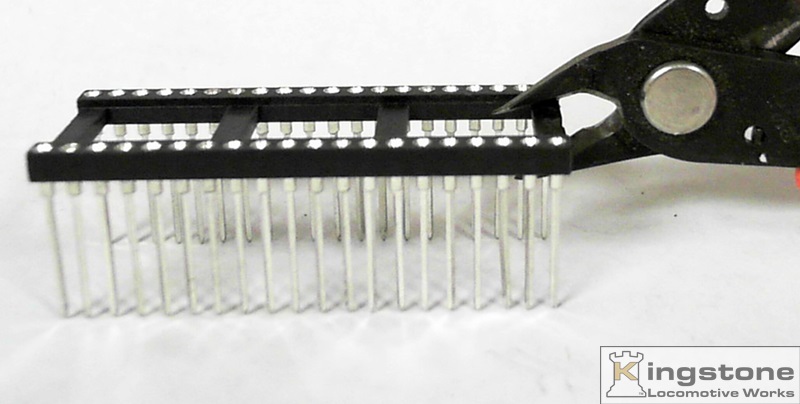

I cut the center bars out of the 40 pin DIP sockets. |

|

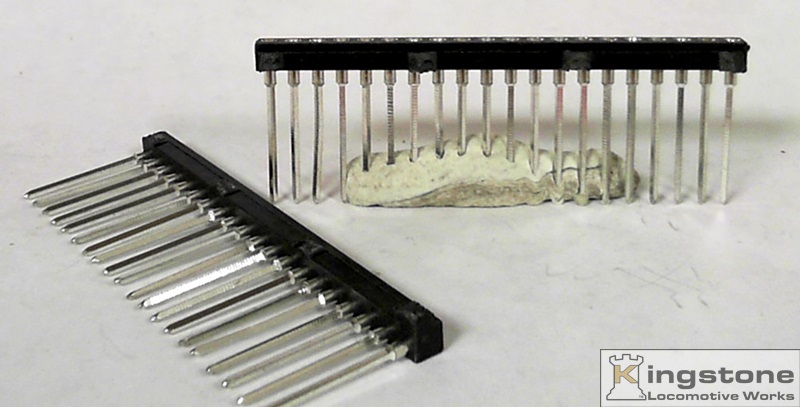

Then I cut off as many pins as I'll need. |

|

I'll need two 4 pin rows and one two pin row. The long legs are cut to the length I need. |

|

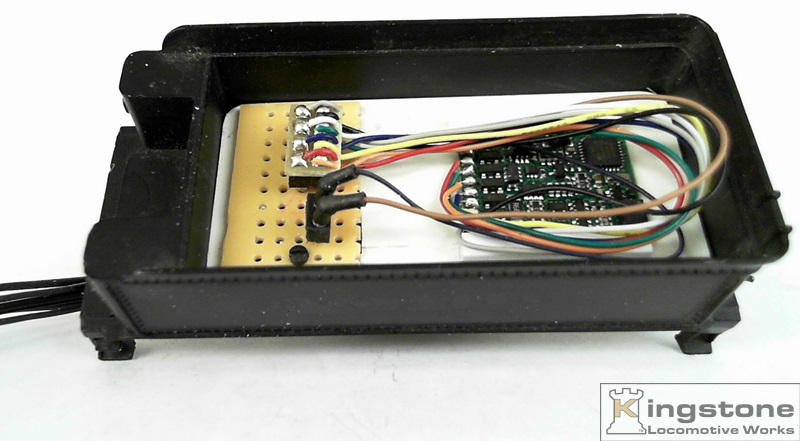

Here they are just stuck into the perf board. |

|

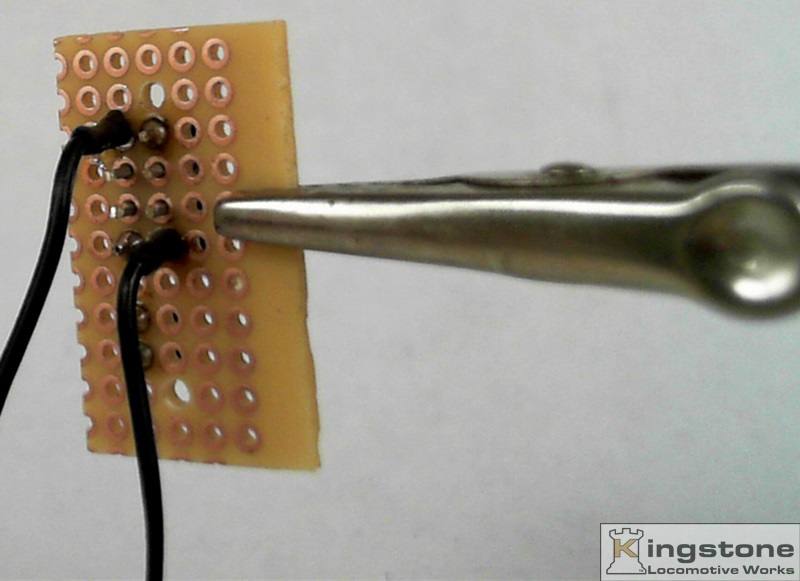

Here the wires that come from the wipers on the wheel have been soldered on. |

|

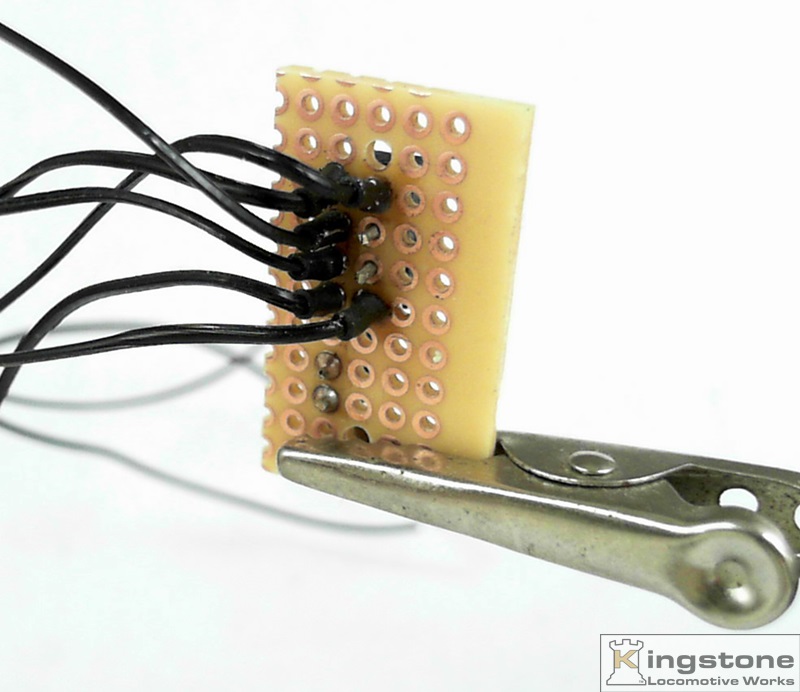

All the wires are needed have been soldered on. The wires will be "wrung" out when they get connected to

the |