![]()

![]()

|

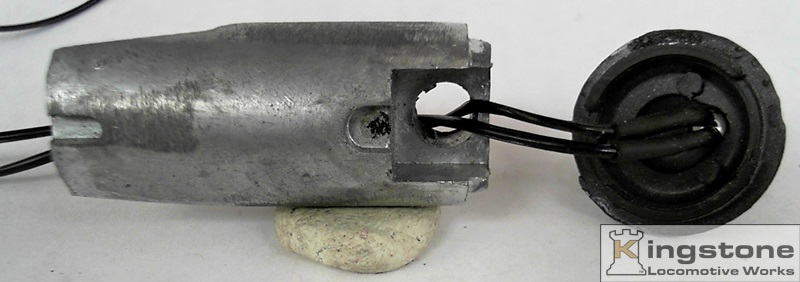

You're looking at the top of the weight. The LED has been firmly pushed into where the plastic lens used

to be. |

> > |

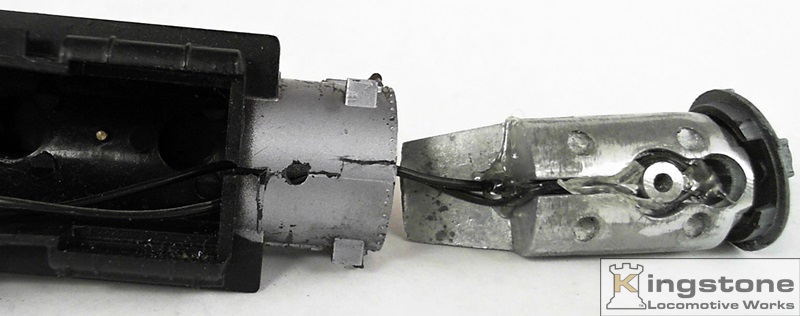

The wires were run through the wire channel and held in place with a couple of dabs of hot glue. |

|

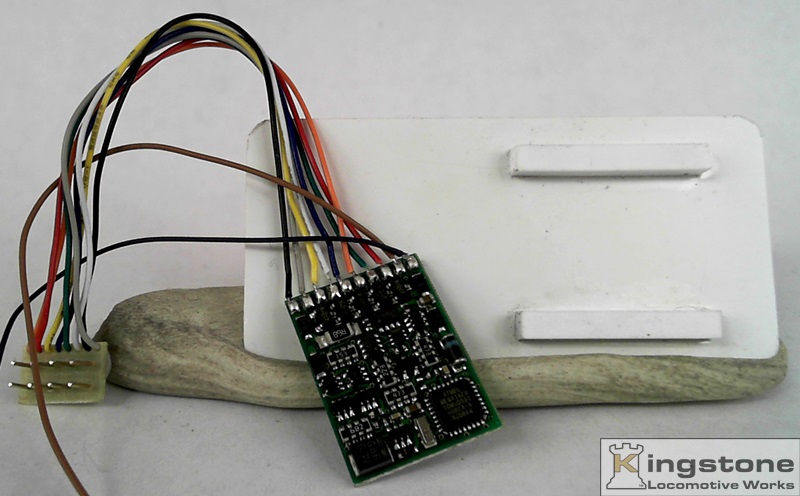

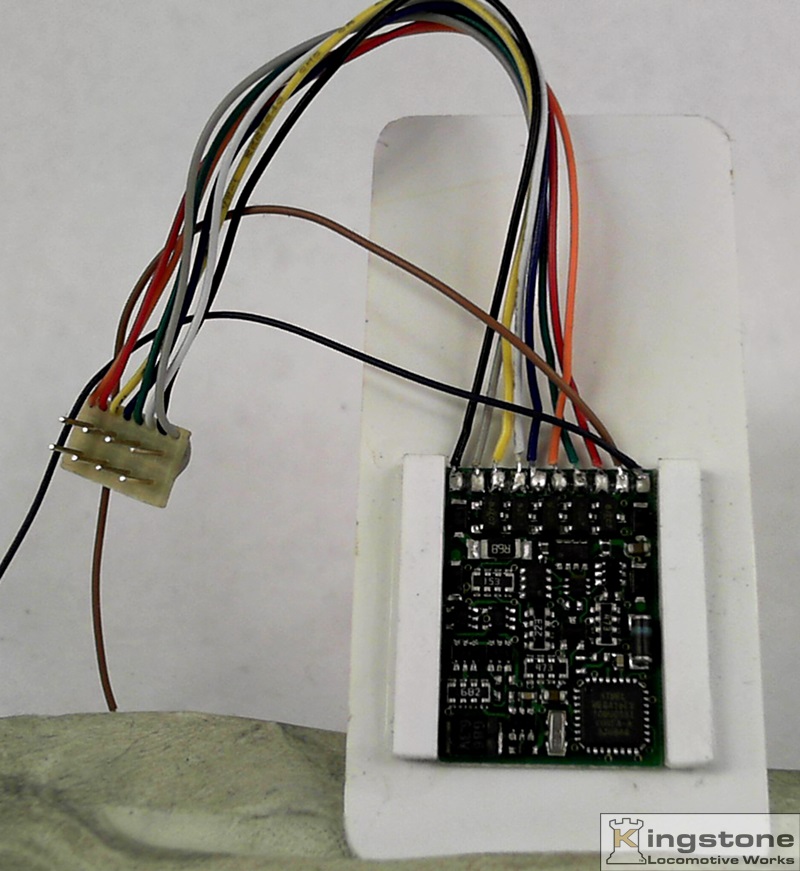

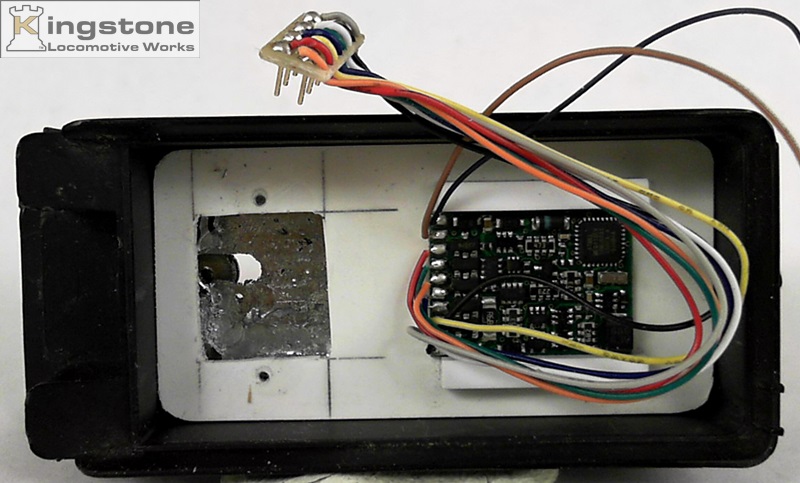

A piece of .060" thick styrene and two 1/4"square pieces were usedto hold the decoder board with a frinction fit. |

>

> |

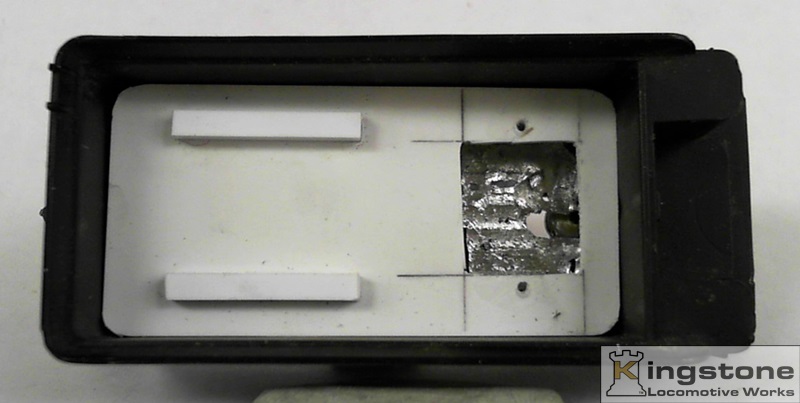

The decoders sub base had a hole cut out for perf board. Two holes were drilled and tapped for an 0-80 screw. |

|

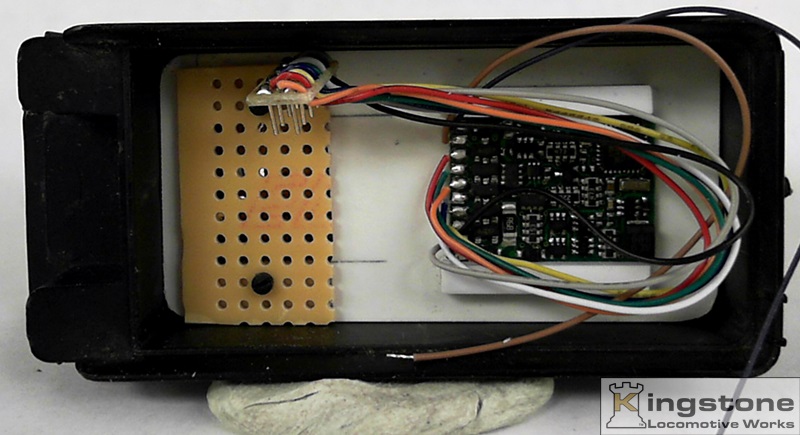

Here the perf board is screwed down to the sub base and installed in the tender to check for fit. |

I make up my own mini custom female plugs. I find the commercial plugs to high in priced plus restrictive in

there use by the way they are

manufactured. I looked an Miniatronics plugs and had sticker shock, plus I think $10 for shipping is kind of high. So, I

made my own. Here's

what I use. They are called machine tooled IC DIP sockets. Jameco part number 114412 for the 28 pin DIP and 94503 for the 40 pin DIP.

Link to

Jameco Parts