Diesel Dockside Switcher

Older projects I started and want to see finished

I started this project back sometime in 2012. This is a metal casting by Cary which

is no longer in business.

Apparently Bowser bought them out. I'm going to change from the rubber band drive to a gear drive using some

left

over Hobbytown of Boston drive gears. Another company no longer in business.Discovered years later Hobbytown of Boston is still around under

new ownership, |

NOTE:Click on picture to enlarge. Click back button on your browser to return to this page.

|

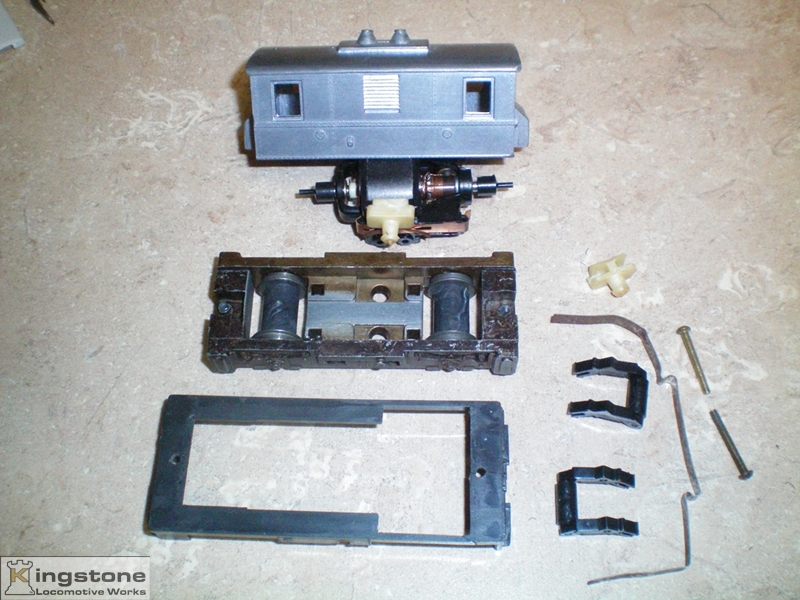

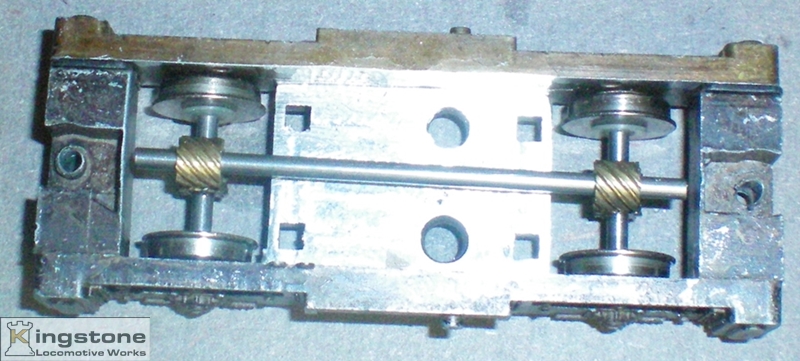

| View of the Atheran Hustler truck and Cary body plus the rubber band drive. |

|

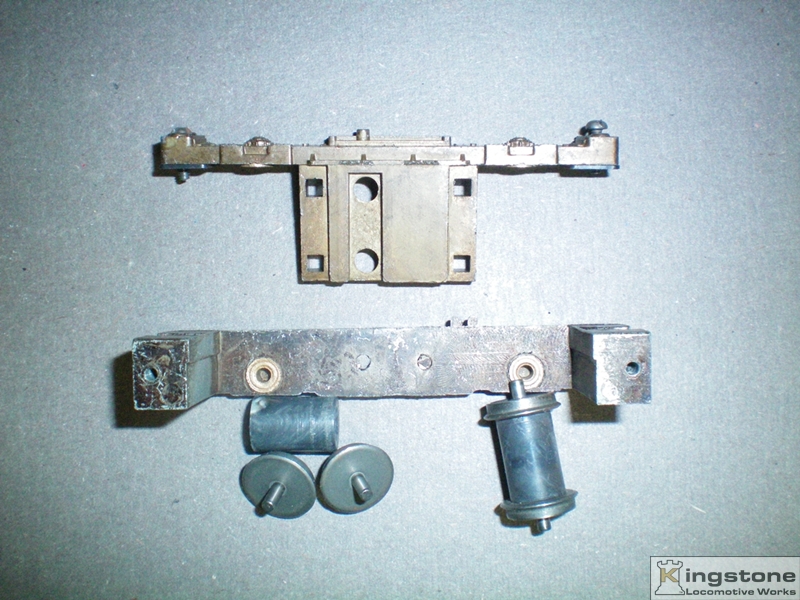

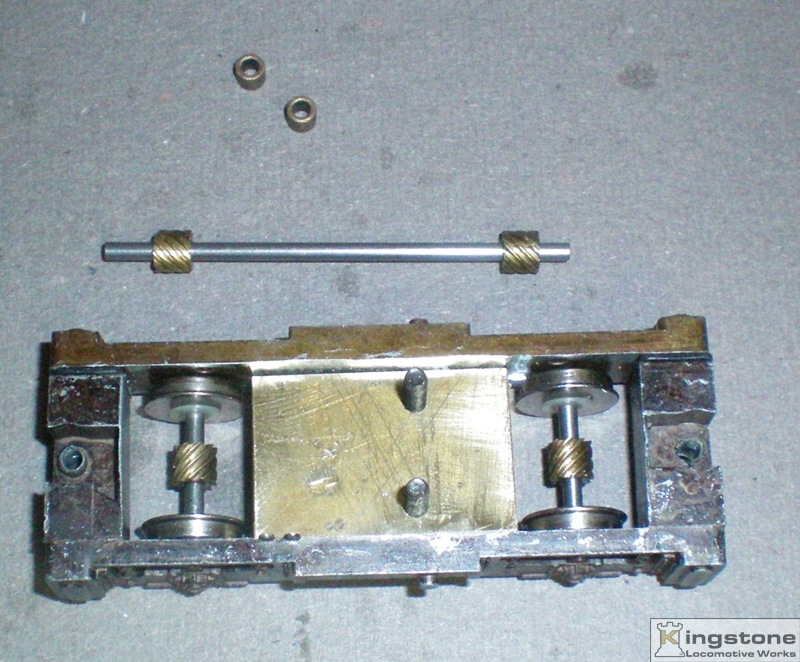

| Chassis and wheels taken apart. |

|

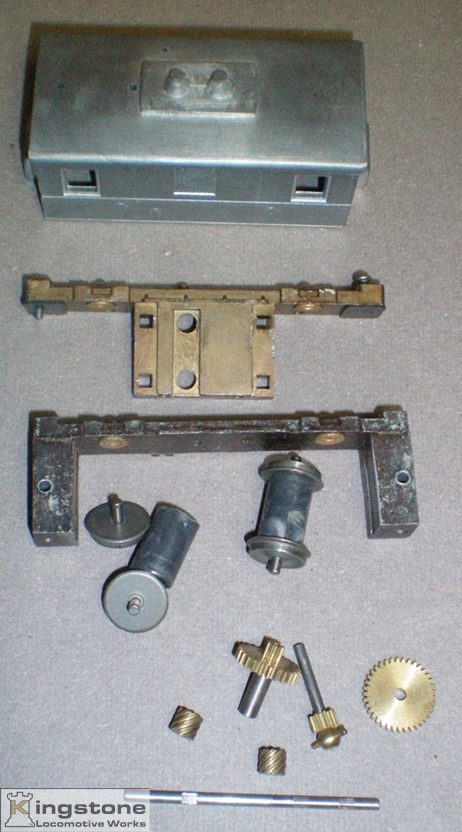

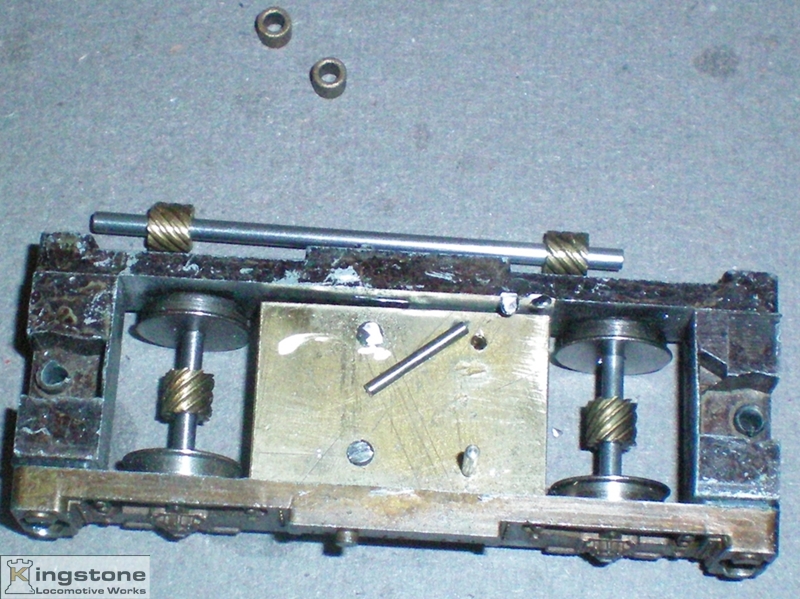

| Another parts picture plus the gearing I'd like to use from the Hobbytown drive. |

|

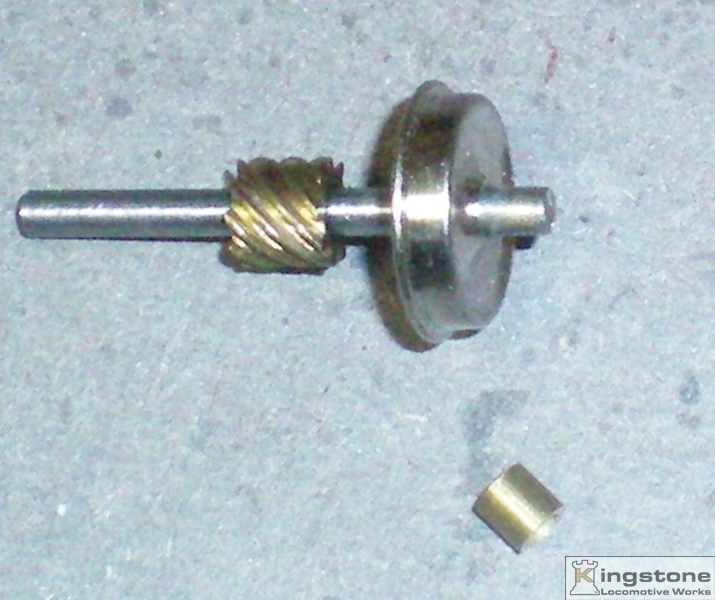

These set of wheels are nickel plated. I had them in my wheel

scrap box. The gears are from a Hobby Town

drive and the axles

are .092" drill rod. Just the right od for the wheel and gear id's.

The brass tubing is used to space the gear and

wheels. The larger

is used to set the gear in the middle of the axle. The shorter one is

used to space the wheel the correct distance in

from the end. |

|

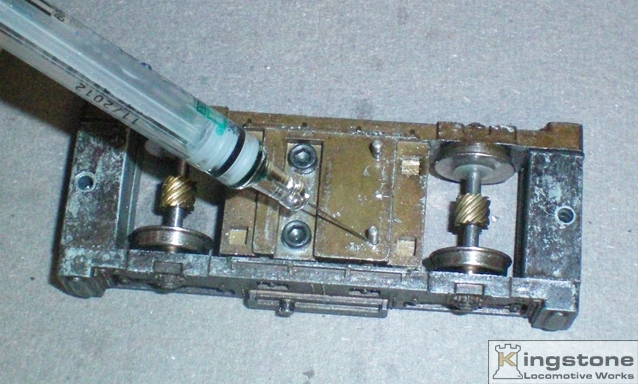

This view shows using the longer brass tube to position the gear

before using Locite© 290 Thread Locker© to hold the gear on the

shaft. The gears and wheels were a nice sliding fit on the shafts.

That's the reason to use a locking compound. |

|

| Once the locking compound had set up on the gear the wheel was spaced using the shorter tube. |

|

| The tube on the axle. |

|

| Side view of the tube on the axle. |

|

| Locking compound was then applied on the one set of wheels and left to set over night. |

|

Once the left side wheels had set up I added the right side wheels

and set the proper gauge. One thing I failed to document

was the

fact that I needed to add an insulator bushing on the right set of

wheels. |

|

| In this view you can see the wheels toward the top of the picture have the insulating bushing on. I had to drill out the wheel

to fit the plastic bushing and then the bushing to fit the axle. No locking compound was added. The plastic holds the wheel good enough. Then a

temporary axle shaft was cut and the second set of gears were temporarily placed on them to check for height off of the bottom. |

|

| The bottom was milled to about .070" thickness at it's thinnest point. |

|

| A piece of 3/16" thick brass plate was machined to fit into the bottom and secured with two 4-40 screws. |

|

| Next two 1/16" dia. holes were drilled through the bottom and the brass plate for locating pins. This helps to realign the gears after disassembly for maintenance. |

|

| Green Loctite was used to secure the pins from falling out. |

12/2/11 : I've run into a gearing problem. The Hobbytown gears I wanted to use will not work. |