![]()

NOTE:Click on picture to enlarge. Click back button on your browser to return to this page.

Here's a better view of the "H" channel glued to the gripper. I made them about 5/16" long and glued them close to the front of the gripper so it will clear the back side. |

With the dumper in the load/unload car position you can see how much the grippers need to come down to hold the car. |

I measured the distance from the top of the hopper to the bottom of the gripper. It was about 3/4". So next I had to shorten them up. |

I used a set of side cutters to cut off the cam riders. If you build this kit to be able to use plain hopper cars then this should be done before complete assembly of the rotary drum. |

|

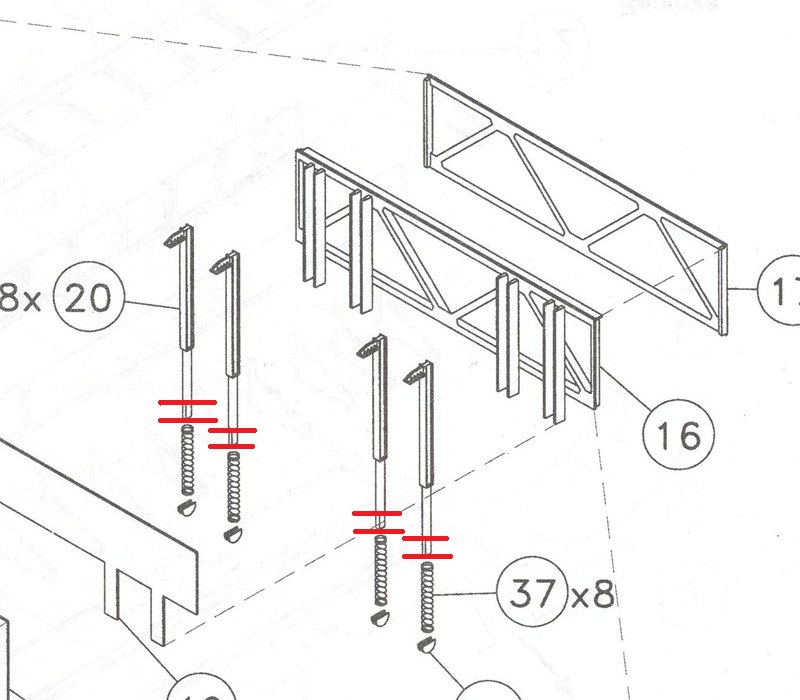

The red lines on the diagram show where to cut the bottom of the gripper shaft. File flat and file the cam rider flat then glue on the bottom. |

The red lines on the diagram show where to cut the bottom of the gripper shaft. File flat and file the cam rider flat then glue on the bottom. |

To finish off the holding grippers I glued on an "T" beam made from a piece of .060" thick by .109" wide on a piece of 2" X 12" HO scale styrene. This was glued to the bottom of the "H" channel. |