![]()

NOTE:Click on picture to enlarge. Click back button on your browser to return to this page.

|

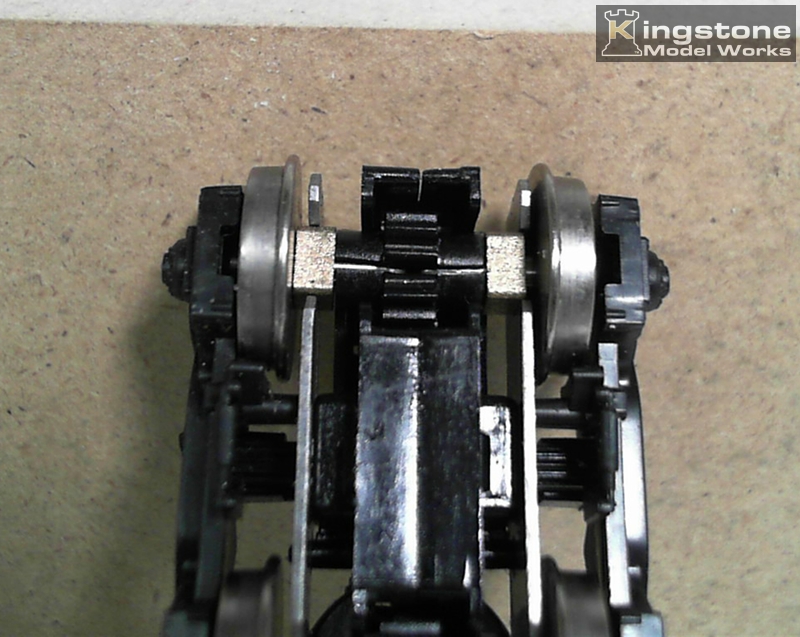

Typical split gear on an |

|

The collar fix. The ID of each collar is different because the OD of the hub on either side |

|

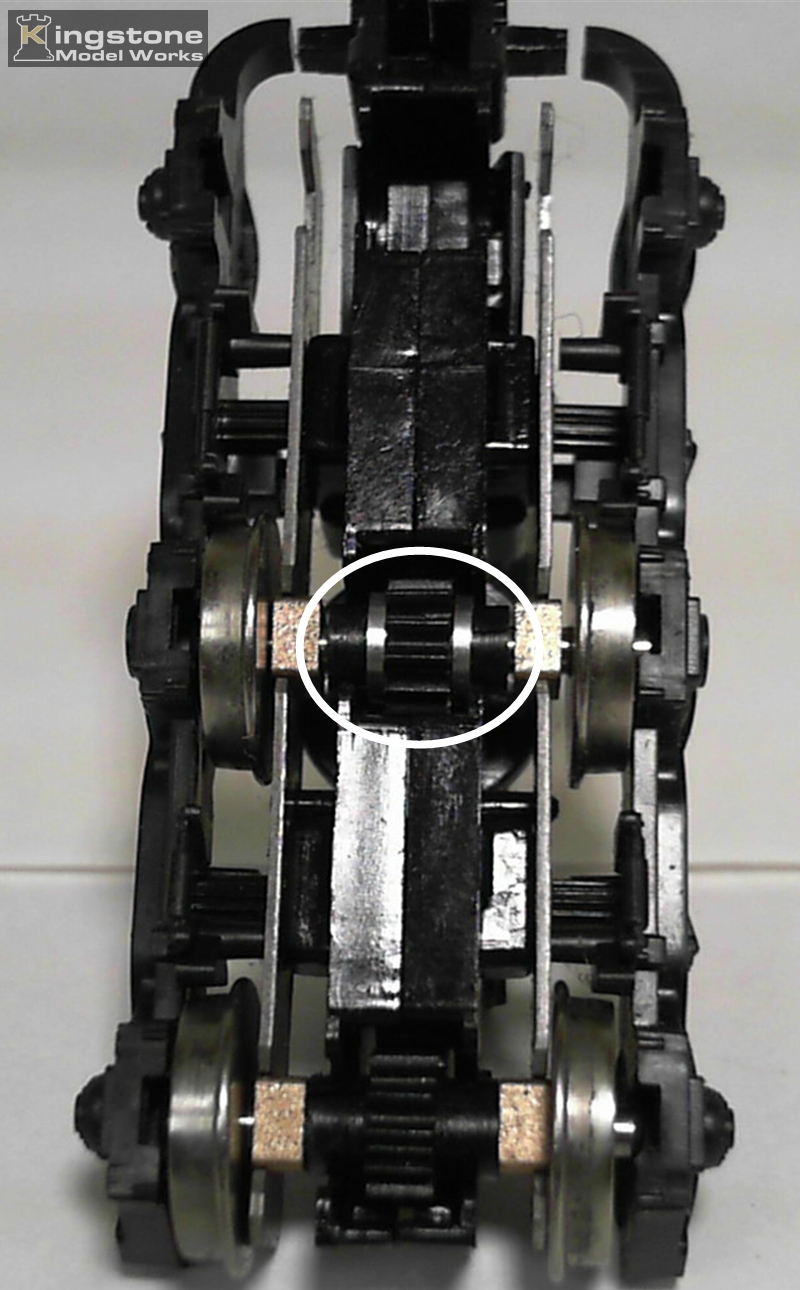

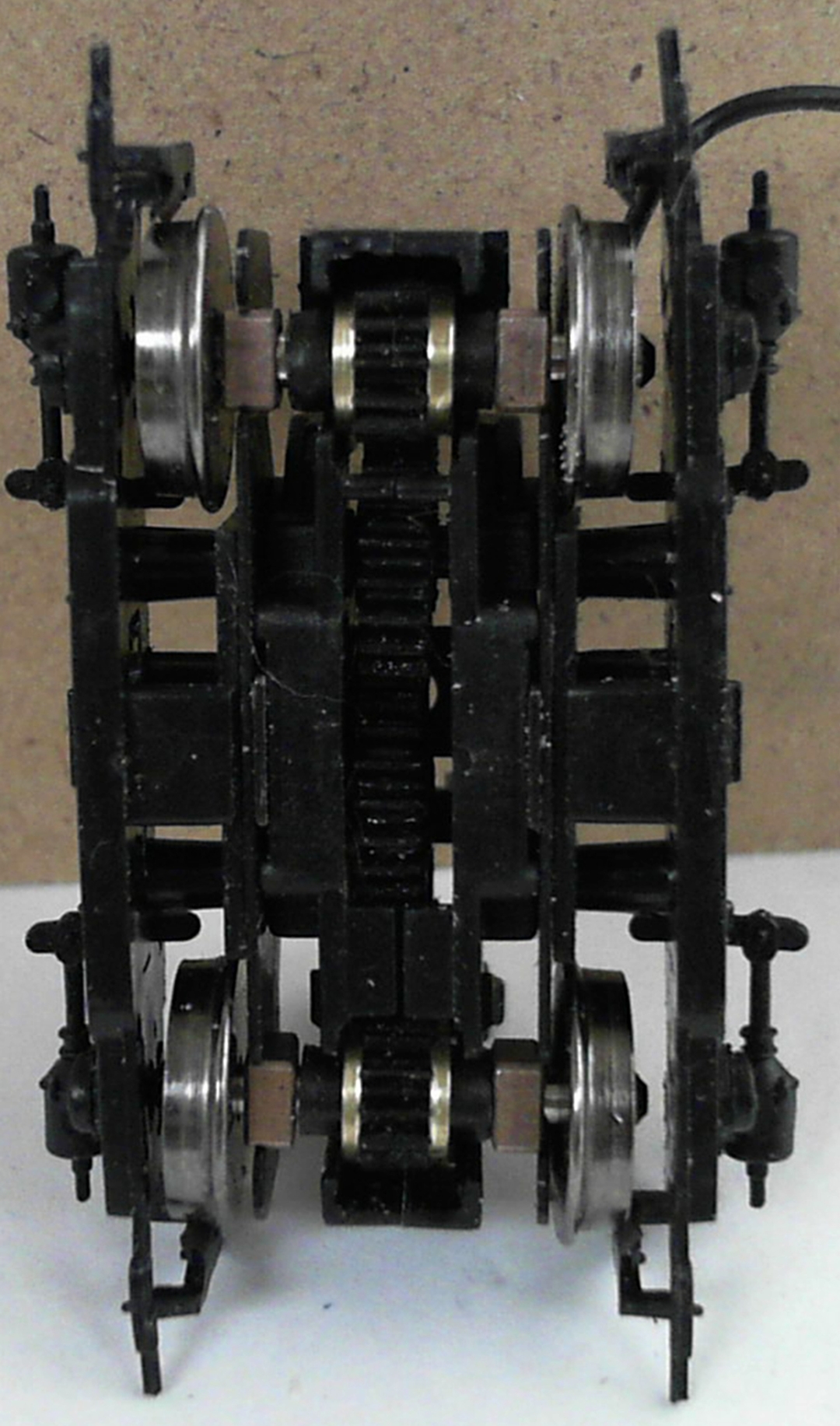

Note the circled gear and the aluminum collars. They are very narrow to fit inside the plastic gear housing.. |

|

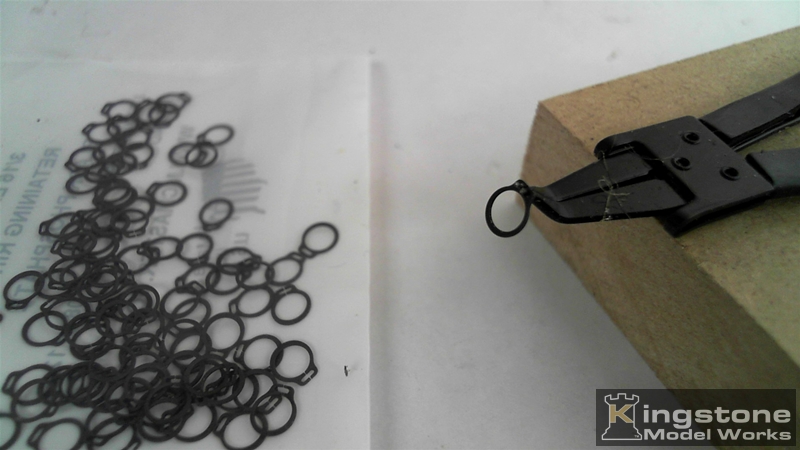

Retainer ring mounted on ring pliers. |

|

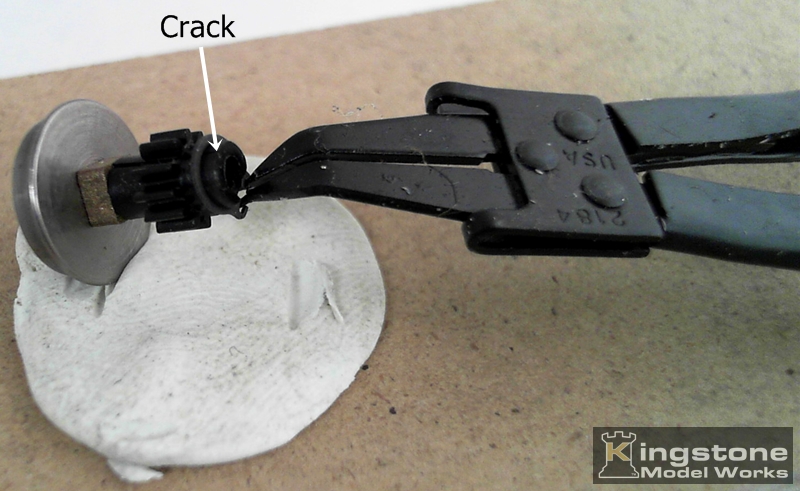

Placing a retainer ring on the hub of the gear. The open portion of the retainer ring goes 180° from the crack. |

|

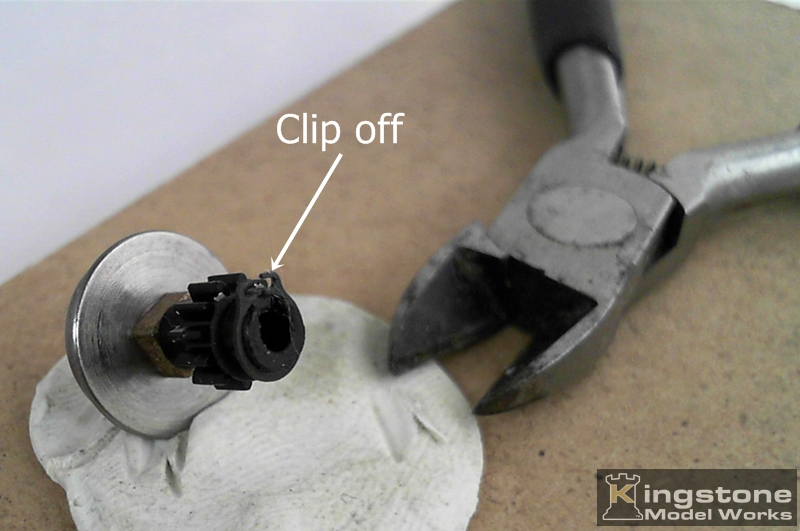

Better view of the ear that needs to be removed. |

|

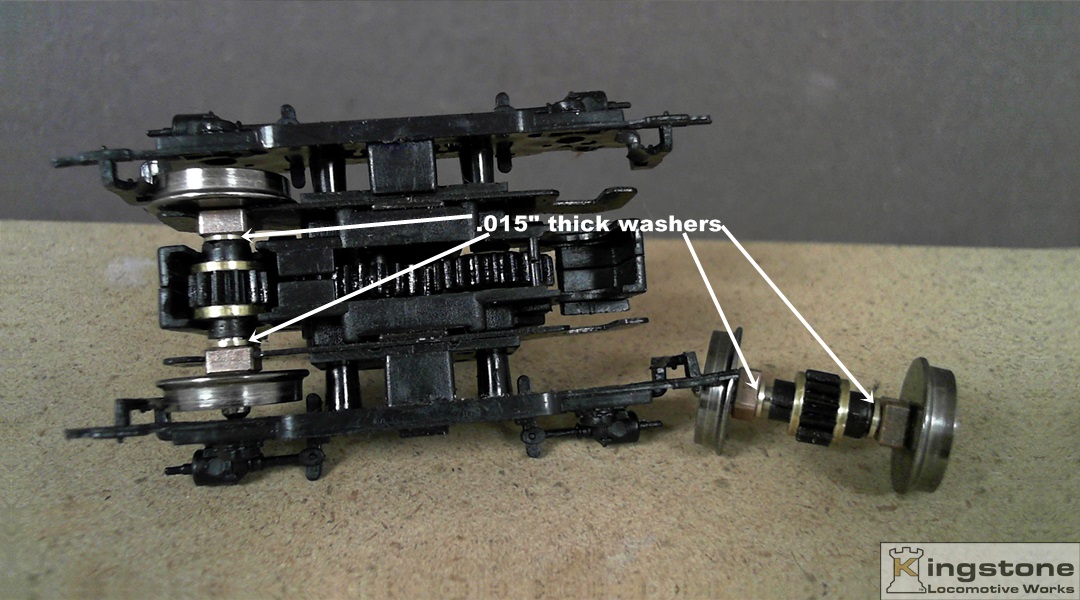

Here's a picture of a later model Athearn truck that has |

|

NOTE: I've done more testing of using the collars to fix the gear problem. Some trucks ran fine others still

have the clicking noise when they hit the tooth area with the split in it. I've also made washers to fit between

the bronze wheel bearing and the

gear to keep the axle centered better on the Athearn truck shown in the last

picture above. So the conclusion is that it's not a 100% fix. I have

another idea that I want to try out and will

post that here when testing is complete.

As of today (1-5-2024) more information has been gathered. Time for an update.

It will be posted as soon as I sift through all the inofrmation.